Top Benefits of Using Submersible Trash Pumps for Efficient Waste Removal

When it comes to efficient waste removal, one of the most effective tools available is the submersible trash pump. These pumps are designed to operate underwater, making them ideal for managing large volumes of water mixed with debris, sediment, and other materials. Their versatility allows them to be used in various applications, including construction sites, sewage systems, and flood control, making them an invaluable asset for both professionals and homeowners alike.

One of the primary benefits of using a submersible trash pump is its capacity to handle solids, which traditional pumps often struggle with. This capability not only enhances efficiency but also reduces the risk of clogs and downtime. Additionally, submersible trash pumps are engineered for durability, ensuring that they can withstand harsh conditions and operate reliably over extended periods. Their compact design also allows for easy transportation and installation, further contributing to their appeal in waste management tasks.

In summary, the submersible trash pump stands out as a powerful solution for effective waste removal, combining strength, reliability, and convenience. By understanding the significant advantages these pumps offer, users can make informed decisions to improve waste management processes, thus achieving greater efficiency and productivity in their operations.

Overview of Submersible Trash Pumps and Their Functionality

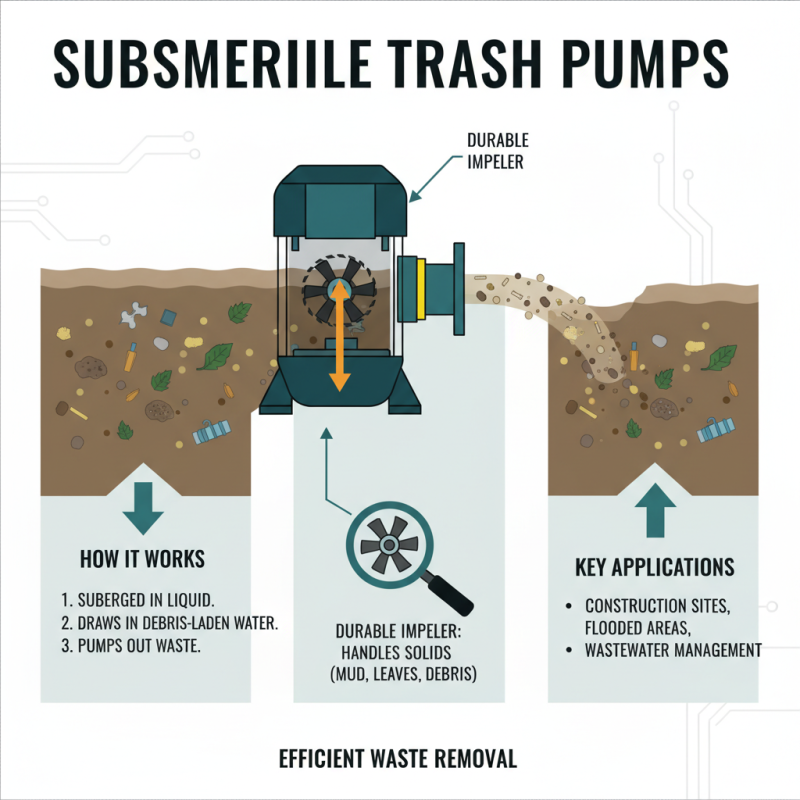

Submersible trash pumps are specialized equipment designed for effective waste removal in various settings, from construction sites to flooded areas. These pumps operate by submerging them in water or liquid, allowing them to draw in debris-laden water through their intake. The unique design typically features a hard, durable impeller capable of handling solids, such as mud, leaves, and other types of waste, efficiently pumping them out while leaving cleaner water behind.

One of the critical functionalities of submersible trash pumps is their ability to operate in both shallow and deep water environments. This versatility makes them indispensable for industries that deal with large volumes of waste, as they can be deployed in scenarios where conventional pumps might struggle. Furthermore, their enclosed design keeps the motor protected from debris and water, enhancing both performance and longevity. Overall, the combination of robust construction and effective waste handling capabilities makes submersible trash pumps a go-to solution for reliable waste removal anytime efficient operation is required.

Key Advantages of Using Submersible Trash Pumps for Waste Removal

Submersible trash pumps offer several key advantages that make them an essential tool for efficient waste removal in various settings. One of the primary benefits is their ability to handle large volumes of waste and debris without clogging. These pumps are designed to operate while submerged in water, allowing them to pick up and transport not only liquids but also solid waste materials like mud, sand, and other refuse. This versatility increases efficiency, particularly in construction sites, drainage applications, and emergency flood situations.

Another significant advantage is the compact design of submersible trash pumps. Unlike traditional pumps that require a complex setup, submersible pumps can be easily deployed in tight spaces and difficult-to-reach areas. This feature facilitates quick waste removal, reducing downtime during projects or emergency responses. Additionally, their mobility allows operators to swiftly relocate pumps as needed, making them adaptable to varying waste management needs. With their efficiency and reliability, submersible trash pumps are a valuable solution for effective waste removal in diverse environments.

Comparison with Traditional Trash Pumps: Efficiency and Performance

When comparing submersible trash pumps to traditional trash pumps, the efficiency and performance differences become strikingly clear. Submersible pumps operate underwater, which allows them to handle large volumes of wastewater and solid debris without the need for priming. This design not only increases their pumping efficiency but also minimizes the risk of cavitation, a common issue with surface-mounted pumps. As a result, submersible pumps can maintain optimal performance over extended periods, making them ideal for continuous waste removal applications.

In terms of versatility, submersible trash pumps outperform their traditional counterparts. They are specifically engineered for varied environments, from construction sites to flooded basements, and can manage a wide range of waste materials, including sludge and debris. Traditional trash pumps, in contrast, often require more maintenance and can struggle with solid materials. The ability of submersible pumps to function effectively under water straightens their reliability, as they can begin pumping immediately without needing to lift the water, further enhancing their overall efficiency in waste management scenarios.

Top Benefits of Using Submersible Trash Pumps vs Traditional Trash Pumps

This chart illustrates the efficiency ratings of Submersible Trash Pumps in comparison to Traditional Trash Pumps. The Submersible Trash Pumps demonstrate higher efficiency due to their design and operational capabilities.

Applications of Submersible Trash Pumps in Various Industries

Submersible trash pumps are indispensable tools in various industries due to their versatility and efficiency in waste removal. In construction sites, these pumps are employed to manage water and debris that accumulate during excavation and site preparation. Their ability to handle large volumes of solids makes them ideal for removing sludge, sediment, and other construction-related waste, ensuring that the site remains operable and safe for workers.

In the wastewater management sector, submersible trash pumps are crucial for the effective pumping of sewage and industrial effluents. These pumps can operate in flooded environments, making them suitable for use in sewage treatment facilities, where they facilitate the movement of waste substances from one location to another. Additionally, the agricultural industry utilizes submersible trash pumps for irrigation and drainage purposes. They help in managing waterlogged fields, allowing farmers to maintain optimal soil conditions and enhance crop yield. The adaptability of submersible trash pumps across these diverse applications underscores their essential role in efficient waste management.

Top Benefits of Using Submersible Trash Pumps for Efficient Waste Removal

| Application Area | Key Benefits | Typical Capacity | Industry Examples |

|---|---|---|---|

| Construction Sites | Efficient removal of debris and water, preventing site flooding | Up to 2,000 GPH | Commercial construction, roadworks |

| Flood Management | Rapid water removal, reducing property damage | Up to 5,000 GPH | Municipal services, emergency response |

| Mining Operations | Handles slurry and debris efficiently | Up to 3,500 GPH | Mining, quarrying |

| Agriculture | Efficient irrigation and water removal from fields | Up to 1,500 GPH | Farming, irrigation systems |

| Wastewater Treatment | Efficient pumping of waste and sludge | Up to 4,000 GPH | Municipal wastewater plants, industrial wastewater management |

Maintenance Tips for Optimal Performance of Submersible Trash Pumps

To maintain the optimal performance of submersible trash pumps, a rigorous maintenance routine is essential. According to a study by the Hydraulic Institute, regular maintenance can increase pump efficiency by as much as 30%. One of the key maintenance practices is to routinely check the pump's inlet screen for clogs. This simple step can prevent debris buildup, ensuring that the pump operates without unnecessary strain. Additionally, it's important to inspect the electrical components and connections frequently, as worn or corroded parts can lead to malfunction, thereby impacting overall waste removal efficiency.

Another critical aspect of maintaining submersible trash pumps is ensuring proper lubrication. The American Society of Mechanical Engineers (ASME) recommends checking the lubrication levels at least once a month. Insufficient lubrication can lead to mechanical failures, contributing to costly downtimes. Furthermore, operators should also monitor the pump's operating temperature, as excessive heat can indicate mechanical issues or overload conditions. By adhering to these maintenance tips, waste management operations can ensure their submersible trash pumps function effectively, ultimately leading to reduced costs and increased longevity of the equipment.

Related Posts

-

Why You Should Choose a Submersible Sump Pump for Your Home Drainage Needs

-

Understanding the Fundamentals of Inline Pumps for Efficient Fluid Management

-

Top Trends in Water Pumps: Harnessing Data-Driven Insights for Optimal Performance in 2023

-

Top Factors Influencing Water Pump Price You Need to Know

-

Why Choosing a High Quality Centrifugal Pump Is Essential for Your Business

-

Unlocking the Power of Submersible Water Pumps: Your Guide to Efficient Water Management

COMPANY INFO

Copyright © 2025. Rotech Pumps & Systems Inc. All rights reserved.