2026 Best Centrifugal Pump Options for Your Needs?

As industries grow, the demand for efficient machinery rises. Centrifugal pumps are vital in various applications. They move liquids with ease and precision. John Smith, an industry expert, once stated, "Choosing the right centrifugal pump can make all the difference in operational efficiency."

However, selecting the best centrifugal pump can be challenging. There are numerous options available in the market. Factors like flow rate, material, and size affect performance. Many buyers feel overwhelmed by technical specifications. Often, they overlook critical details. It's essential to understand your specific needs before making a decision.

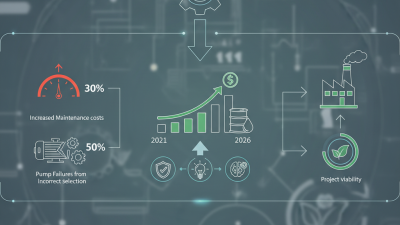

In our exploration of the 2026 best centrifugal pump options, we will highlight key features and considerations. Understanding common pitfalls can prevent costly mistakes. With the right information, selecting an effective centrifugal pump is possible. Yet, even experienced users should approach the process with care. The right pump is not just about fitting the machinery; it’s about meeting performance expectations.

Understanding the Basics of Centrifugal Pumps

Centrifugal pumps are crucial in various industries, from water treatment to chemical processing. They operate by converting rotational energy into kinetic energy. This process creates a flow that moves liquid through a system. According to the Hydraulic Institute, centrifugal pumps account for about 80% of all pumps used in industrial applications.

The efficiency of these pumps can significantly impact operational costs. Reports indicate that optimizing pump efficiency can lead to energy savings of up to 20%. However, not every application will benefit from a traditional centrifugal pump. Issues like viscosity and solids content in the fluid can hinder performance. Selecting the right pump requires a thorough understanding of the specific fluids and the operational environment.

Centrifugal pumps can sometimes exhibit cavitation problems. This phenomenon occurs when vapor bubbles form and collapse within the pump, causing damage. Understanding the NPSH (Net Positive Suction Head) required and available is vital for preventing such issues. Evaluating these factors can be complex. Many users may overlook critical data, leading to suboptimal performance. Ensuring that the chosen pump fits the application's unique demands is essential, yet can often be a challenging task.

Key Factors to Consider When Choosing a Centrifugal Pump

When selecting a centrifugal pump, several factors are crucial. Efficiency, flow rate, and pressure are essential metrics. For instance, a recent industry report indicates that pumps can operate at up to 90% efficiency. This high performance can lead to significant energy savings, up to 30% lower operational costs.

Consider the size and design of the pump. A pump that is too large can waste energy. Conversely, a small pump may not meet your needs. It's crucial to match the pump design with the specific fluid characteristics. Viscosity affects the flow rate. Thicker fluids may require specialized impellers for optimal performance.

Tips: Always review application data. Understand your fluid's properties. Temperature and corrosiveness can impact material selection. Seek expert advice if you're unsure about specifications. Regular maintenance is key. Neglect can lead to reduced lifespan and more repairs. Make an effort to balance cost with quality; cheaper pumps may lead to long-term issues.

2026 Centrifugal Pump Performance Comparison

This chart compares the flow rates of different centrifugal pumps based on performance metrics. Evaluating these options can assist in selecting the right pump for your specific needs in various applications.

Top Centrifugal Pump Brands and Their Features for 2026

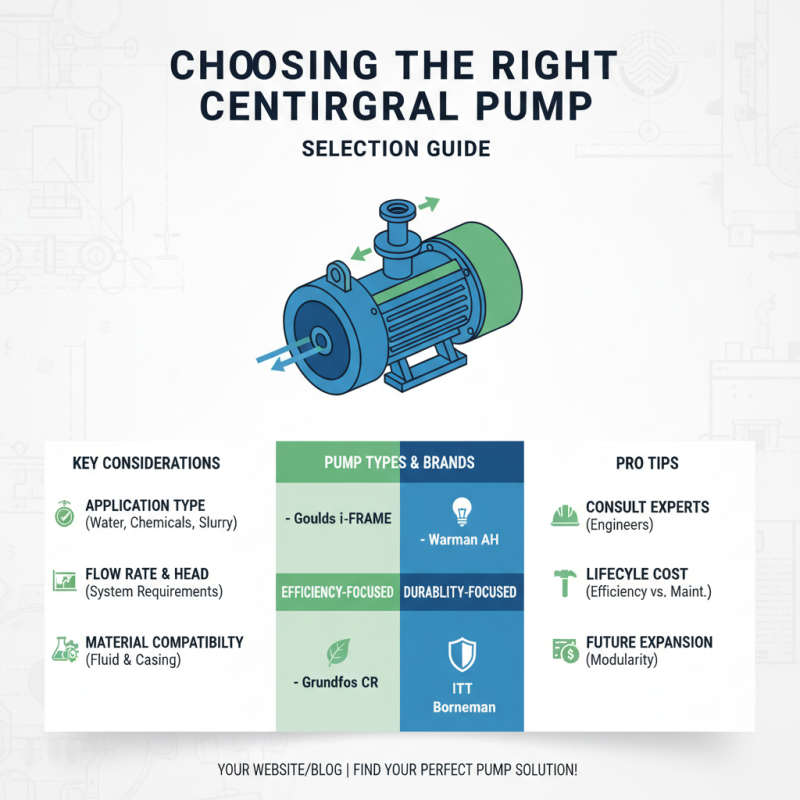

Choosing the right centrifugal pump can be challenging. The market offers various brands, each with unique features. Some pumps focus on efficiency, while others prioritize durability. Consider the specific application when selecting a pump.

Pay attention to materials used. For corrosive substances, choose pumps made from resistant materials. This feature extends the pump's lifespan.

Tips: Evaluate the flow rate and pressure requirements. A mismatch can lead to inefficiencies. Engage with professionals who can offer insights. They often share practical experiences that might not be found in product descriptions.

Don't forget maintenance needs. Some pumps require frequent servicing, while others are low-maintenance. Weigh your options based on your time availability. Reflect on whether you can dedicate resources for upkeep.

Consider also the noise levels of the pump. Some might be louder than anticipated. This factor can influence your working environment. Research user reviews to gauge real-world experiences. The more informed your choice, the better your results will be.

Comparative Analysis of High-Performance Centrifugal Pumps

When selecting a high-performance centrifugal pump, several factors come into play. Flow rate is crucial. A pump's capacity to move a specific volume of liquid determines its effectiveness in various applications. Efficiency is another key consideration. Pumps should operate with minimal energy consumption to reduce operational costs. Understanding the specific needs of your system can help in making the right choice.

Compatibility matters as well. A pump must suit the type of fluid being processed. For example, some liquids are corrosive and require specialized materials. This adds complexity to the selection process. Not all options fulfill these criteria perfectly. Often, compromises must be made, leading to potential inefficiencies or operational challenges. It's essential to weigh performance against cost and maintenance needs.

Durability is a vital component too. Pumps can endure wear and tear over time, affecting their performance. Regular maintenance is imperative. Some models may require more attention than others. This can lead to unexpected downtime, which can be costly. Assessing all these aspects is important to find the best centrifugal pump for your needs. Balancing performance and practicality ensures the most effective solution for your specific application.

2026 Best Centrifugal Pump Options for Your Needs

| Model | Flow Rate (GPM) | Max Head (Feet) | Power (HP) | Efficiency (%) | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | 300 | 150 | 10 | 85 | 75 |

| Model B | 400 | 180 | 15 | 90 | 80 |

| Model C | 500 | 200 | 20 | 92 | 85 |

Maintenance Tips for Longevity of Centrifugal Pumps

Centrifugal pumps are essential in many industries, from agriculture to wastewater treatment. Proper maintenance can greatly enhance their lifespan. One crucial tip is to frequently check for leaks. Any sign of leakage can lead to reduced efficiency. Another aspect is to monitor the pump's vibration. Unusual vibrations might signal underlying problems, like misalignment or wear.

Regularly inspect the pump's seals and bearings. These components often wear out over time. If they’re not replaced, you may face unexpected failures. Cleaning the pump casing is also vital. Dirt can accumulate, impacting performance. Pay attention to the fluid being pumped. Abrasive materials can damage internal parts quickly.

Consider routine lubrication. Ensure that moving parts have enough grease or oil to function smoothly. Neglecting lubrication can lead to friction and heat, which are harmful. Lastly, keep a record of maintenance activities. This helps track patterns and predict future needs. Each pump is unique, so don’t overlook any detail.

Related Posts

-

Why Choosing a High Quality Centrifugal Pump Is Essential for Your Business

-

Why Choosing the Right Pump Manufacturers is Crucial for Your Project Success?

-

Ultimate Pump Catalog Guide with Top 10 Pump Types to Maximize Efficiency

-

How to Choose the Best Electric Water Pump for Your Needs in 2025

-

Best Electric Water Pumps for Home Use in 2023 Reviews and Buying Guide

-

Top Trends in Water Pumps: Harnessing Data-Driven Insights for Optimal Performance in 2023

COMPANY INFO

Copyright © 2025. Rotech Pumps & Systems Inc. All rights reserved.