Why Choosing the Right Pump Manufacturers is Crucial for Your Project Success?

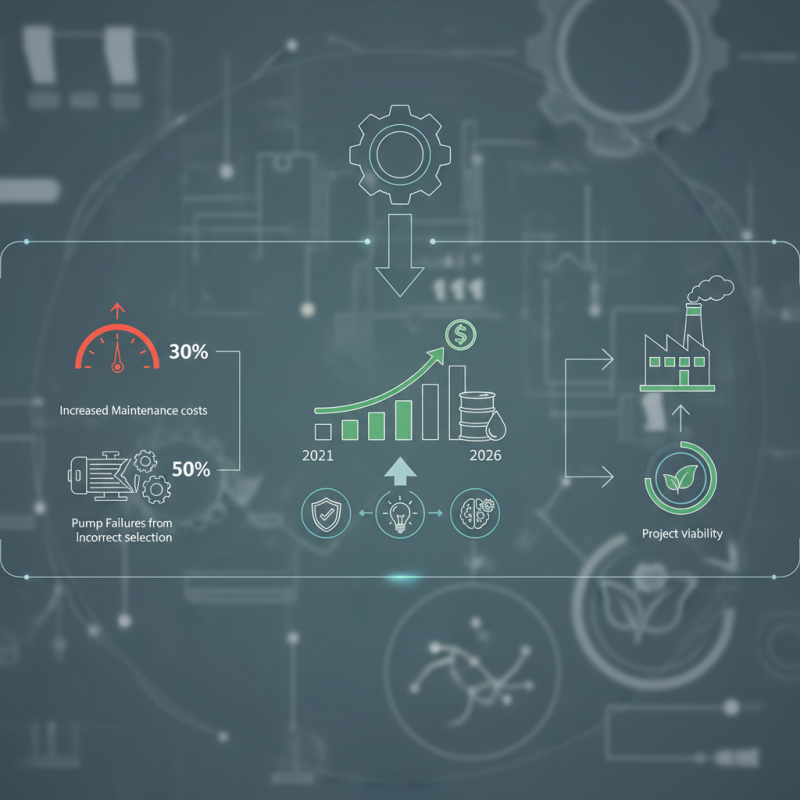

In the realm of industrial projects, the significance of selecting the right pump manufacturers cannot be overstated. Research indicates that improper pump selection can lead to operational inefficiencies and increased maintenance costs, which can escalate to as much as 30% of the overall project budget. According to a recent report from the Hydraulic Institute, approximately 50% of all pump failures stem from inadequate sizing and selection processes. Therefore, understanding the intricacies involved in choosing a manufacturer is paramount for ensuring a project’s success.

Moreover, the global pump market is poised to reach a valuation of over $80 billion by 2026, reflecting a compound annual growth rate (CAGR) of around 4.5% from 2021. This growth underscores the evolving demands of industries relying on high-performance pumps for various applications, from water treatment to oil and gas exploration. A reliable pump manufacturer not only guarantees quality products but also offers expert knowledge and innovative solutions that can adapt to specific project requirements. By aligning with capable pump manufacturers, project leaders can enhance efficiency, longevity, and overall project viability.

Understanding the Importance of Pump Manufacturers for Project Success

Choosing the right pump manufacturer can significantly impact the success of any project, particularly in industries like construction, oil and gas, and water management. According to a report by the Hydraulic Institute, nearly 30% of pump failures are attributable to manufacturer-related issues, including subpar quality and inadequate customer support. This highlights the necessity of selecting a reputable pump manufacturer that aligns with project specifications and demands. A reliable partner not only ensures the quality of the pumps but also provides crucial technical support to avoid costly delays and complications during project execution.

Moreover, industry statistics indicate that a well-planned pump selection process can improve system efficiency by up to 25%. This is particularly vital in applications where energy consumption and operational costs are significant considerations. A reputable pump manufacturer will offer a comprehensive range of products that can be tailored to specific project requirements, enhancing both performance and reliability. Furthermore, their expertise can lead to better integration of pump systems within the broader project framework, thereby bolstering project timelines and budgets.

Ultimately, making an informed choice in pump manufacturing partners is an integral step that can substantially drive project success and sustainability in the long term.

Key Factors to Consider When Selecting Pump Manufacturers

When selecting pump manufacturers for your project, several key factors must be considered to ensure success. First and foremost, the manufacturer's experience and reputation in the industry play a critical role. According to a recent report by the Pump Industry Analysis Group, companies with over 20 years of experience tend to have lower failure rates in their products, as evidenced by a 30% reduction in warranty claims compared to newer manufacturers. This highlights the importance of choosing a manufacturer known for reliability and proven performance.

Another crucial aspect is the manufacturer’s capability to provide customized solutions. Each project has unique requirements, and the best manufacturers should be able to offer tailored pumping solutions that meet specific operational needs. In fact, industry surveys show that 70% of project managers prefer working with manufacturers that can adapt designs and specifications to fit their project parameters. Additionally, evaluating the after-sales support and service capabilities is essential; a robust support system can significantly reduce downtime, ensuring that your project remains on schedule and within budget.

Lastly, considering the sustainability practices of the manufacturer is increasingly vital. As the industry moves towards greener practices, selecting a manufacturer committed to eco-friendly solutions can enhance your project's overall sustainability profile. Reports indicate that pumps designed with energy efficiency in mind can lead to a 15-25% reduction in operating costs, thereby contributing to both economic and environmental benefits. Making informed decisions based on these factors can greatly impact the success and efficiency of your project.

Impact of Quality Control on Pump Performance and Reliability

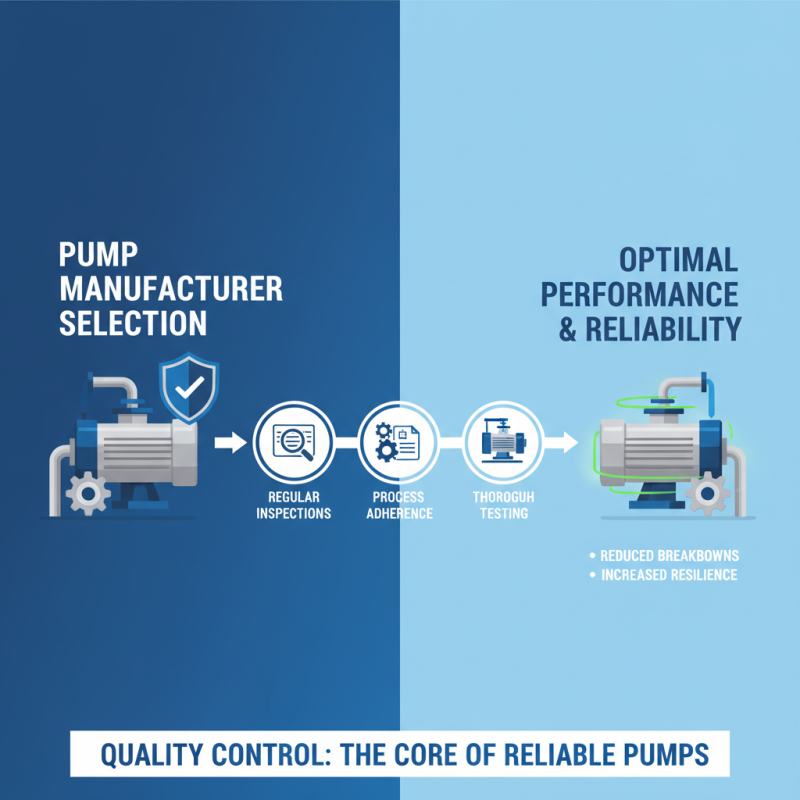

When selecting pump manufacturers for a project, the emphasis on quality control is critical for achieving optimal performance and reliability. Quality control encompasses a range of processes designed to ensure that every pump meets stringent performance standards and operational safety requirements. This includes regular inspections, adherence to manufacturing process regulations, and thorough testing protocols that address potential failures. A manufacturer that prioritizes robust quality control measures will produce pumps that are more resilient to wear and tear, significantly reducing the risk of breakdowns during critical operations.

Moreover, effective quality control not only enhances the lifespan of the pumps but also directly influences operational efficiency. Pumps that are built to high-quality standards are less likely to experience inefficiencies that can arise from mechanical failures or inadequate design. Projects relying on dependable pump performance can avoid costly downtimes and maintenance issues. Thus, investing time in selecting a manufacturer with a verified quality control system can lead to long-term success and reliability, ensuring that projects are completed within their timelines and budgets.

Evaluating Manufacturer Reputation and Industry Experience

When embarking on a project that requires pumps, evaluating the manufacturer's reputation and industry experience becomes a critical step. A manufacturer with a strong reputation often signifies reliability and commitment to quality. Their established presence in the industry not only reflects their ability to adapt to changing market demands but also indicates a history of successfully completed projects. This track record can provide valuable insights into their product performance, customer service, and overall trustworthiness, thus reducing the risks of project delays or equipment failures. Moreover, a manufacturer with substantial industry experience possesses an invaluable depth of knowledge regarding the specific challenges and intricacies related to pump applications. They are likely to have encountered various scenarios throughout their years of operation, allowing them to offer tailored solutions that meet unique project requirements. This expertise is particularly important in complex projects where understanding the nuances of pump systems can significantly impact efficiency and longevity. Collaborating with a seasoned manufacturer ensures that you benefit from their experience and insights, leading to a more successful project outcome.

The Role of Technical Support in Smooth Project Execution

When embarking on a project that requires pumps, the selection of the right manufacturer plays a pivotal role in ensuring optimal performance and efficiency. Technical support is an integral component in this equation, often determining the smooth execution of your project. A proven manufacturer offers not only high-quality products but also the expertise needed to navigate any complexities that may arise during installation and operation. Having access to experienced technical support means that potential issues can be resolved quickly, minimizing downtime and keeping the project on track.

**Tips**: When evaluating pump manufacturers, inquire about their technical support services. Ensure that they provide access to knowledgeable personnel who can assist you both pre- and post-installation. Additionally, consider manufacturers that offer comprehensive documentation and resources, which can be invaluable during the project lifecycle.

Effective communication with technical support can significantly influence project outcomes. Establish a clear line of communication with your chosen manufacturer from the outset; this ensures that any concerns or questions can be addressed promptly. Regular check-ins during critical phases of the project can help preemptively identify potential challenges, allowing your team to adapt without the stress of unexpected disruptions.

**Tips**: Create a checklist of technical support expectations, such as response times and availability. This will help you articulate your needs and ensure that you select a manufacturer who aligns with your project’s demands. Regularly updating your project team on any feedback or changes suggested by the technical support team will promote a collaborative environment and encourage proactive problem-solving.

Why Choosing the Right Pump Manufacturers is Crucial for Your Project Success? - The Role of Technical Support in Smooth Project Execution

| Criteria | Importance Level (1-5) | Potential Impact | Technical Support Availability |

|---|---|---|---|

| Product Quality | 5 | High | 24/7 Support |

| Technical Expertise | 4 | Medium | On-site Consulting |

| Response Time | 5 | High | Immediate Response |

| Customization Options | 3 | Medium | Limited Availability |

| Documentation | 4 | Medium | Comprehensive Manuals |

Related Posts

-

Top Trends in Water Pumps: Harnessing Data-Driven Insights for Optimal Performance in 2023

-

Top Benefits of Using Submersible Trash Pumps for Efficient Waste Removal

-

Top Factors Influencing Water Pump Price You Need to Know

-

Top 10 Tips for Choosing the Best Water Pump for Your Home

-

Unlocking the Power of Submersible Water Pumps: Your Guide to Efficient Water Management

-

The Essential Guide to Self Priming Centrifugal Pumps: How They Work and Their Key Applications

COMPANY INFO

Copyright © 2025. Rotech Pumps & Systems Inc. All rights reserved.