How to Choose the Right Types of Pumps for Your Needs

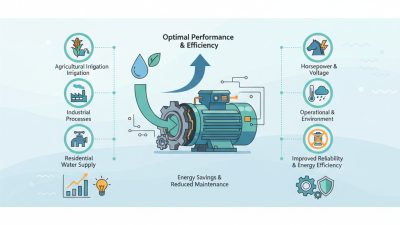

Choosing the appropriate types of pumps for specific applications can significantly enhance operational efficiency and reduce costs in various industries. According to a recent report by Grand View Research, the global pump market size is expected to reach $67.5 billion by 2025, driven by increasing demand in the water and wastewater, oil and gas, and energy sectors. This growth underscores the importance of selecting the right pump type that aligns with industry requirements, ensuring durability and functionality.

When assessing the types of pumps suitable for various applications, factors such as the fluid type, pressure, flow rate, and the environment must be considered. The Hydraulic Institute emphasizes that improper pump selection can lead to a decrease in efficiency by up to 40%, resulting in higher operational costs and increased maintenance issues. Therefore, understanding the fundamental differences between various pump types—such as centrifugal pumps, positive displacement pumps, and submersible pumps—becomes crucial for optimizing performance and achieving desired outcomes.

Moreover, with advancements in pump technology, more solutions are now available that cater to specialized needs, including increased energy efficiency, lower emissions, and smart monitoring capabilities. As industries evolve, aligning your pump selection strategy with new technologies and operational demands is essential for maintaining competitive advantages while ensuring compliance with both environmental and safety regulations.

Understanding Different Types of Pumps and Their Applications

When selecting the right pump for your needs, it is crucial to understand the various types of pumps available and their specific applications.

Centrifugal pumps are one of the most common types, utilizing rotational kinetic energy to move fluids through a piping system. They are well-suited for applications involving water transfer, chemical processing, and irrigation. Their ability to handle large volumes makes them ideal for industrial and municipal use, while their straightforward design facilitates easy maintenance.

On the other hand, positive displacement pumps operate by trapping a fixed amount of fluid and forcing it into the discharge pipe, making them especially effective for applications requiring high pressure and precision flow rates. These pumps are commonly used in the food and beverage industry, where they safely move viscous fluids without damaging product integrity.

Additionally, diaphragm pumps, a subtype of positive displacement pumps, are particularly adept at handling slurries and corrosive liquids, making them popular in wastewater treatment and chemical processing. Understanding these differences ensures that you choose the right pump type for your specific application and operational requirements.

Evaluating Your Specific Pumping Needs and Requirements

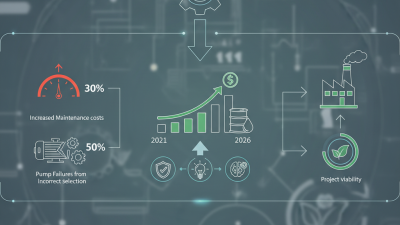

When evaluating your specific pumping needs and requirements, it is crucial to start by identifying the characteristics of the fluid you need to pump. This includes understanding the fluid's viscosity, temperature, and whether it contains any solids or abrasives. According to a report by the Hydraulic Institute, nearly 50% of pump failures can be attributed to improper selection based on these fluid properties. Selecting a pump that can handle these characteristics effectively will greatly enhance reliability and performance.

In addition to fluid characteristics, consider the flow rate and head requirements for your application. The flow rate is the amount of fluid you need to transfer over a specific period, while head refers to the height the fluid needs to be pumped. The American Society of Mechanical Engineers (ASME) reports that up to 10% of energy costs in industrial settings can be attributed to inefficient pumping systems. Therefore, accurately calculating these parameters can help you choose the right pump design, such as positive displacement versus centrifugal pumps, ensuring optimal energy use and operational efficiency in your processes.

How to Choose the Right Types of Pumps for Your Needs - Evaluating Your Specific Pumping Needs and Requirements

| Pump Type | Best For | Key Features | Flow Rate | Typical Applications |

|---|---|---|---|---|

| Centrifugal Pump | Fluids with low viscosity | Simple design, high efficiency | 100-10,000 GPH | Water supply, irrigation |

| Positive Displacement Pump | High viscosity fluids | Consistent flow, pressure generation | 10-1,500 GPH | Food processing, chemicals |

| Submersible Pump | Pumped water from deep underground | Compact, self-priming | 100-4,000 GPH | Sewage, drainage |

| Diaphragm Pump | Chemicals and wastewater | No electricity needed, safe for corrosives | 0.5-150 GPH | Chemical processing, agriculture |

| Peristaltic Pump | Slurries and solids | Gentle pumping action, no contamination | 0.1-300 GPH | Laboratory, food and beverage |

Comparing Performance Metrics: Flow Rate, Pressure, and Efficiency

Selecting the right pump for your specific needs requires a careful analysis of key performance metrics such as flow rate, pressure, and efficiency. Flow rate, typically measured in gallons per minute (GPM) or liters per minute (LPM), indicates how much fluid the pump can move within a given timeframe. The required flow rate can vary significantly based on the application; thus, understanding the demand of your system is crucial. If the flow rate selected is too low, it might lead to inadequate performance, while an excessively high flow rate can lead to operational inefficiencies or damage to the system.

Pressure is another critical metric that needs careful consideration. It represents the force at which the fluid is delivered through the pump and is usually measured in pounds per square inch (PSI) or bar. For applications that require the fluid to overcome significant elevation changes or resistance in piping, a higher pressure rating is essential. It's important to match the pump's pressure rating to the system’s requirements, as the wrong pressure can affect both performance and longevity.

Lastly, efficiency plays a pivotal role in the overall operational costs associated with pump usage. High-efficiency pumps not only consume less power but also reduce the wear and tear on components, ultimately leading to longer service life and lower maintenance costs. When evaluating pumps, consider the efficiency ratings and how they align with your operational goals, as this can significantly impact both performance and economic sustainability in the long run.

Comparison of Pump Performance Metrics

This chart compares three different types of pumps based on their flow rate, pressure, and efficiency. The performance metrics will help you choose the right pump for your specific needs.

Assessing Material Compatibility and Environmental Conditions

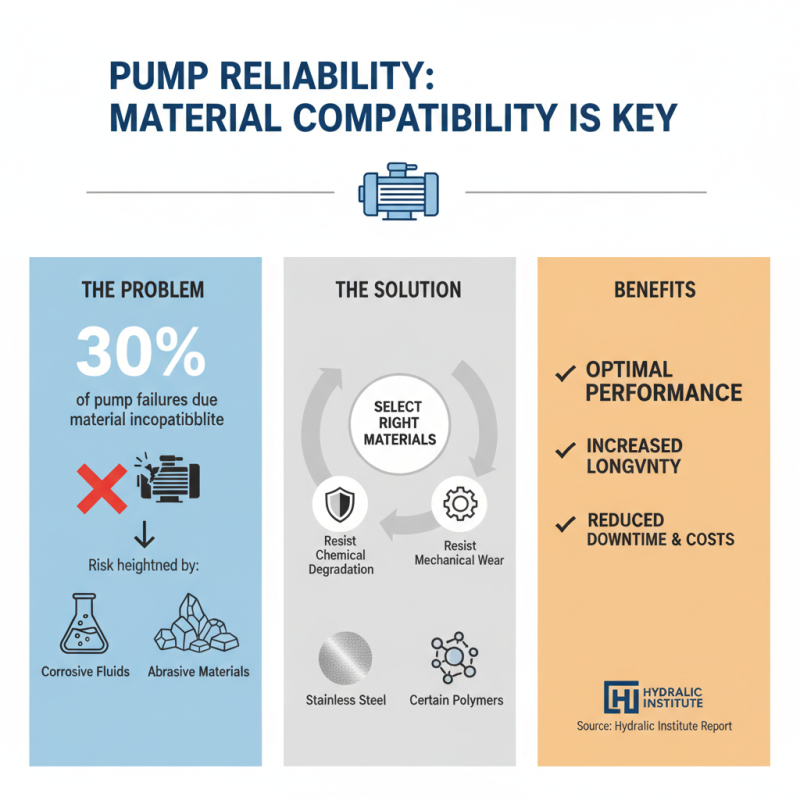

When selecting the appropriate type of pump for specific applications, assessing material compatibility is crucial to ensure optimal performance and longevity. According to a recent report from the Hydraulic Institute, approximately 30% of pump failures can be traced back to material incompatibility issues. This risk is significantly heightened when pumps transport corrosive fluids or abrasive materials. Therefore, it is vital to choose pump materials that resist chemical degradation and mechanical wear, such as stainless steel or certain polymers, depending on the fluid's composition.

Environmental conditions also play a significant role in the selection of pump types. A study published by the American Society of Mechanical Engineers indicates that temperature extremes and exposure to harsh elements can adversely affect pump efficiency and lifespan. For example, pumps operating in high-temperature environments may require specialized seals and lubricants that can withstand elevated heat, while those in outdoor settings must be designed to resist UV radiation and moisture ingress. Understanding the specific environmental factors and the nature of the fluid being handled allows for a more informed decision, ultimately leading to enhanced operational reliability and reduced maintenance costs.

Budgeting and Cost Considerations for Pump Selection

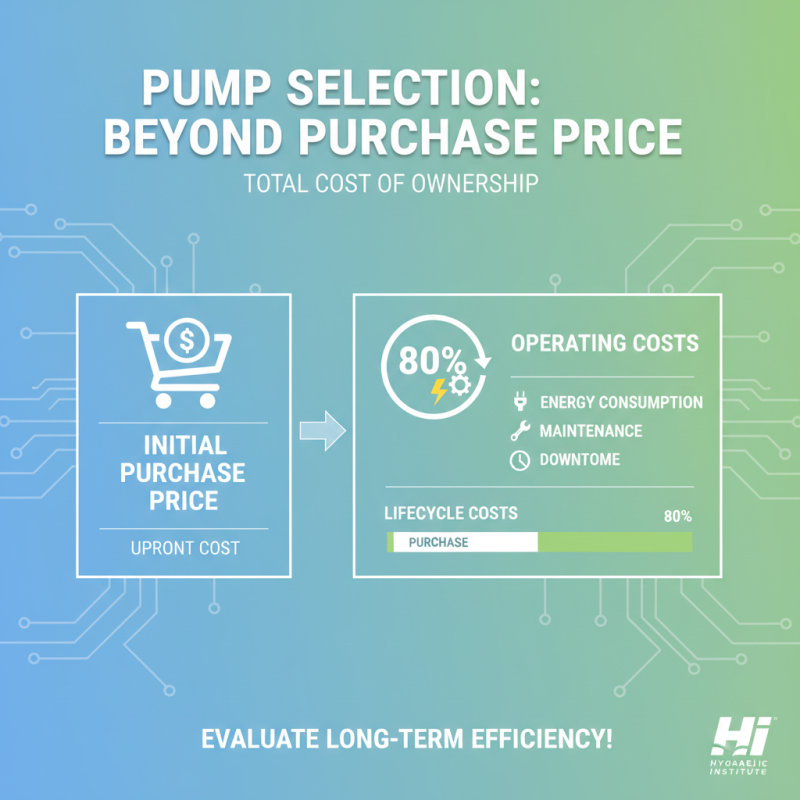

When it comes to selecting the right type of pump for your needs, budgeting and cost considerations play a crucial role. The initial purchase price of a pump is just one aspect of the total cost of ownership. According to a report by the Hydraulic Institute, the operating costs, including energy consumption, maintenance, and downtime, can account for up to 80% of the total lifecycle costs of a pump. Therefore, it’s essential to evaluate not just the upfront costs but also the long-term operational efficiency to make an informed decision.

Different pump technologies can vary significantly in their energy efficiency and maintenance requirements. For example, centrifugal pumps often have lower initial costs but can be less efficient in certain applications compared to positive displacement pumps, which may require a higher initial investment but offer better energy retention and longer service life. A comprehensive analysis of energy consumption trends released by the U.S. Department of Energy found that using efficient pumps can reduce energy costs by up to 40%, highlighting the importance of taking operational efficiency into account alongside initial costs when choosing a pump. By carefully balancing these factors, businesses can make more effective and economical pump selections tailored to their specific operational needs.

Related Posts

-

Ultimate Guide to Using a Pump Catalog with Actionable Tips for Success

-

Understanding the Benefits of Inline Pumps in Modern Water Solutions

-

Why Choosing the Right Pump Manufacturers is Crucial for Your Project Success?

-

Why Choosing a High Quality Centrifugal Pump Is Essential for Your Business

-

Unlocking the Power of Submersible Water Pumps: Your Guide to Efficient Water Management

-

Why You Should Choose the Right Water Pump Motor for Your Needs

COMPANY INFO

Copyright © 2025. Rotech Pumps & Systems Inc. All rights reserved.