Why You Should Choose the Right Water Pump Motor for Your Needs?

Choosing the right water pump motor is crucial for various applications. According to John Smith, a water pump motor industry expert, "Selecting the appropriate motor can significantly impact efficiency." Many people overlook this aspect, which can lead to inefficiencies.

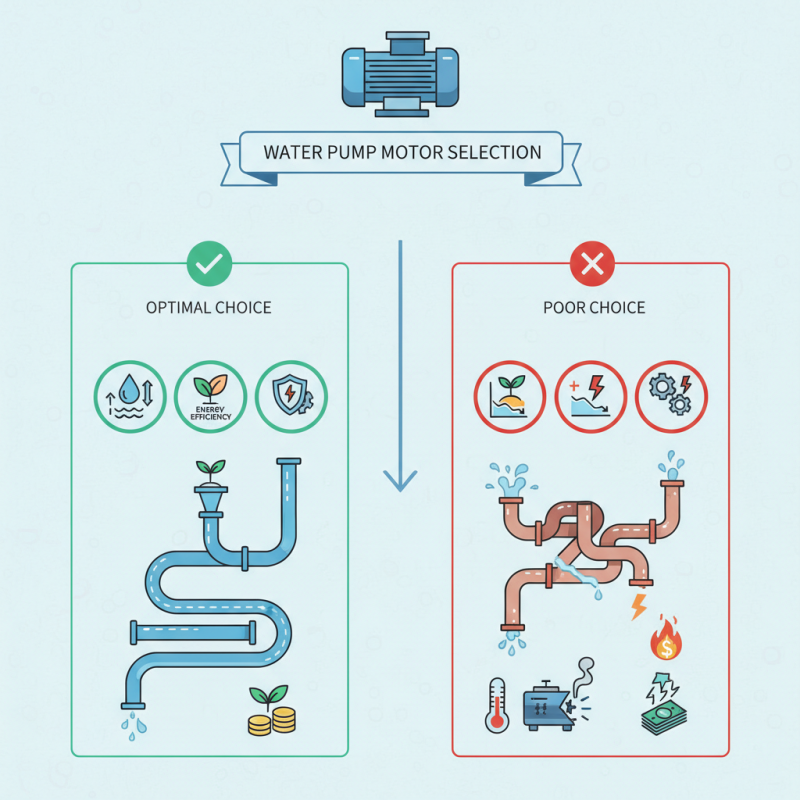

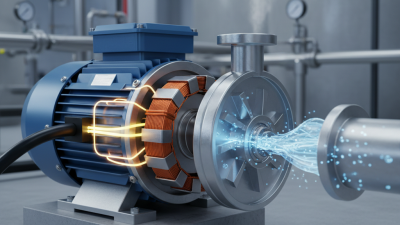

A water pump motor is more than just a mechanical part. It plays a pivotal role in ensuring smooth water flow. An unsuitable motor can cause problems like overheating and increased energy costs. Understanding your needs is essential to avoid these pitfalls.

Consider your specific requirements before making a decision. The wrong choice may lead to unexpected expenses. Reflect on the factors that matter most: flow rate, energy efficiency, and reliability. A well-chosen water pump motor can provide lasting benefits, while a poor selection may result in frustration and waste.

Understanding the Importance of Water Pump Motors for Efficiency

When selecting a water pump motor, efficiency is crucial.

A study by the Hydraulic Institute shows that about 20-25% of the energy consumed globally is used by electric motors. Efficient motors can reduce energy consumption significantly. By choosing the right motor, you can cut operational costs.

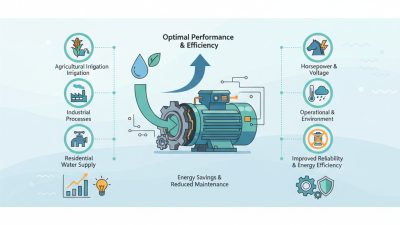

Water pump motors play a significant role in various applications, from agricultural irrigation to industrial processes. According to the U.S. Department of Energy, inefficient motors can waste up to 30% of energy. This inefficiency can lead to increased operational costs and higher greenhouse gas emissions. A more efficient motor may cost more initially, but it pays off in the long run.

However, there are challenges in selecting the right solution. Many users do not fully understand their specific needs. The right motor should match the pump's requirements, including flow rate and pressure. Mismatched components can create inefficiencies, leading to frustration. It's essential to understand the complexities involved in this choice. The wrong selection can result in decreased performance and increased wear and tear on the motor.

Factors to Consider When Selecting a Water Pump Motor

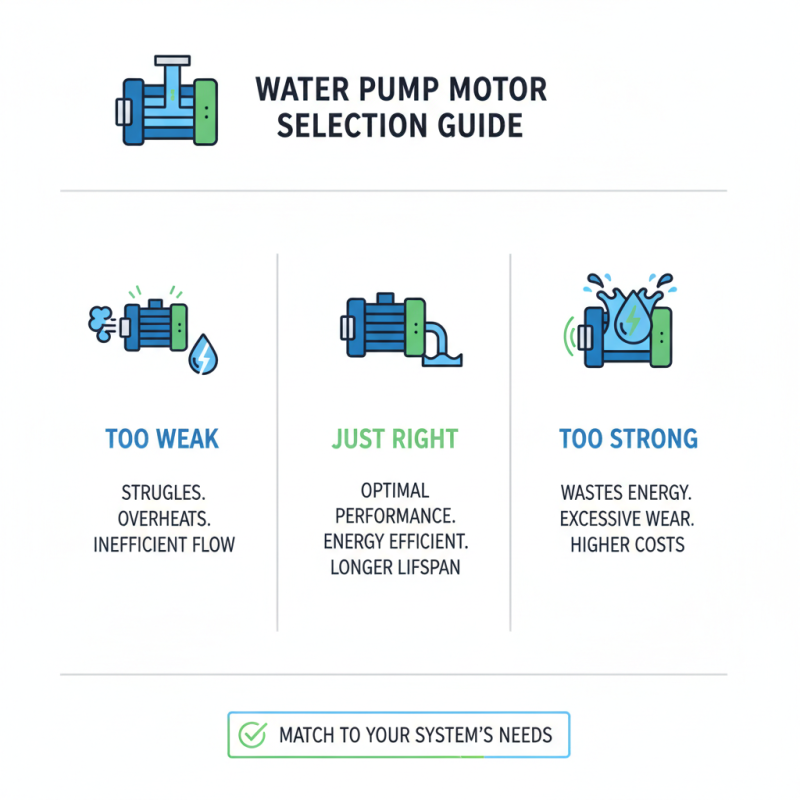

Choosing the right water pump motor is crucial for efficiency. Consider the motor’s power requirements relevant to your system. A motor that is too weak may struggle and overheat. One that is too strong could waste energy. It's important to match the motor to your specific needs.

You also need to evaluate the environment. Motors can be exposed to water or harsh conditions. A motor with appropriate sealing can prevent damage. Noise level matters too. Some motors can be quite loud, which might not be suitable for residential areas.

Pay attention to the pump flow rate. This needs to align with what you require. A mismatch can lead to low performance. Occasionally, people overlook this factor, resulting in frequent malfunctions. Installation space is another key point. Ensure the motor fits comfortably in the designated area. A cramped space can cause heat build-up, leading to premature failure.

Types of Water Pump Motors and Their Applications

Choosing the right water pump motor involves understanding various types and their applications. A centrifugal pump motor is popular for its efficiency in moving water. It's ideal for home irrigation systems, pool maintenance, and industrial applications. These motors can handle large volumes of water quickly, making them a favorite for many users.

Another option is the submersible motor, designed to operate underwater. It's perfect for deep wells and provides a reliable solution for removing groundwater. However, users sometimes overlook the installation requirements. Water quality is also a crucial factor, as certain motors may not endure harsh conditions.

Then there’s the positive displacement motor, which offers precise flow control. These motors are used in applications that require exact measurements, such as chemical processing. People often dislike their complexity, yet their advantages are hard to ignore. Choosing the right motor feels overwhelming, but careful consideration can lead to efficient and long-lasting results.

Why You Should Choose the Right Water Pump Motor for Your Needs?

| Motor Type | Power Range (HP) | Efficiency (%) | Common Applications |

|---|---|---|---|

| Submersible Motor | 0.5 - 10 | 80 - 90 | Deep well pumping, wastewater management |

| Surface Motor | 0.5 - 15 | 75 - 85 | Irrigation, fountain systems |

| Inline Motor | 1 - 20 | 85 - 95 | Aquarium systems, hydroponics |

| Gear Motor | 1 - 5 | 70 - 80 | Industrial applications, conveyor systems |

| Magnetic Drive Motor | 0.5 - 10 | 80 - 90 | Chemicals, liquids with solids |

How to Assess the Power and Performance Requirements

Choosing the right water pump motor requires careful assessment of power and performance needs. Start by determining the flow rate required for your application. This rate defines how much water you need moved in a specific time. For instance, a garden irrigation system may require a different flow rate than a small pond. Understanding these needs helps narrow down your options.

Next, consider the head height your pump must achieve. This refers to the vertical distance the water must be lifted. A pump designed for low elevations may struggle with high head requirements. It’s essential to match the pump's capabilities to your situation. Ignore this factor, and performance will suffer. You might end up with decreased efficiency or excessive energy consumption.

Lastly, think about the environment where the pump operates. Factors like temperature, humidity, and potential debris matter. Selecting a motor ill-suited for harsh conditions could lead to failures. Regular maintenance is also a key point to ponder. It may seem tedious, but neglecting it often results in costly repairs later. Assessing these performance factors ensures your pump operates effectively and reliably over time.

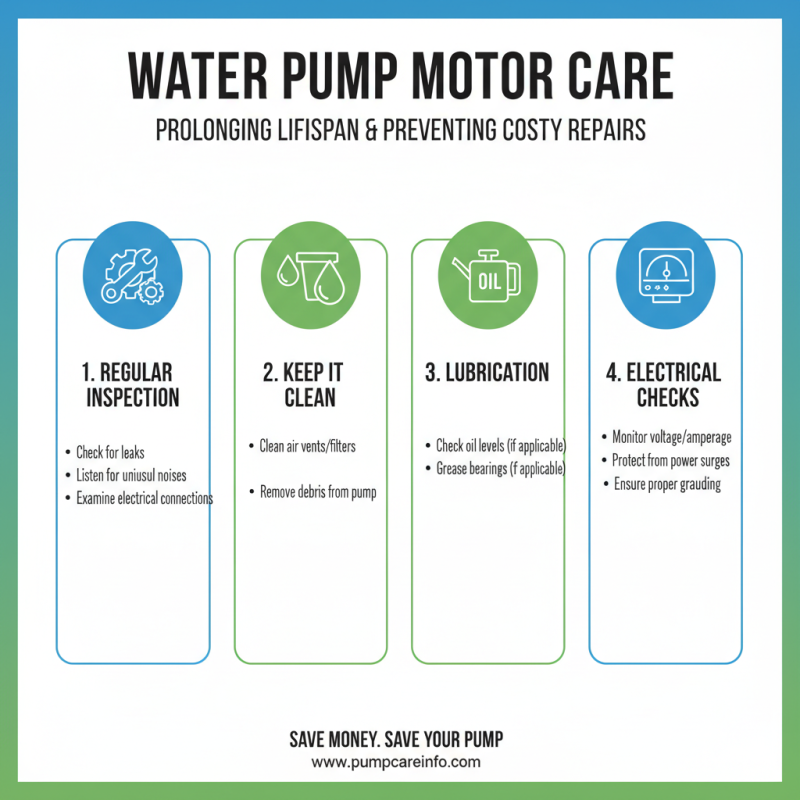

Maintenance Tips for Prolonging Your Water Pump Motor’s Lifespan

Maintaining a water pump motor requires regular attention. Neglect can lead to costly repairs. Here are some essential tips to help prolong its lifespan.

Firstly, keep the motor clean. Dust and debris can hinder performance. Regularly inspect and clean the motor housing to prevent overheating. Use a soft brush or a cloth for this task. Avoid using water directly, as it can damage electrical components.

Another important aspect is lubrication. Check the motor’s bearings regularly. Without proper lubrication, these components can wear down quickly. Use the recommended lubricant to ensure smooth operation. Don't skip this step, as it can lead to decreased efficiency.

Pay attention to vibrations. Unusual vibrations can indicate misalignment or wear. Address these issues promptly. Ignoring them might result in further damage. Regularly check for loose bolts or parts that may need tightening.

Lastly, monitor the motor’s operating environment. Excess humidity or extreme temperatures can affect performance. If possible, install the motor in a well-ventilated area. Shield it from direct exposure to harsh elements to extend its life.

Related Posts

-

Why You Should Choose the Right Water Pump Motor for Your Needs

-

What is a Water Pump Motor and How Does It Work?

-

Why You Should Choose a Submersible Sump Pump for Your Home Drainage Needs

-

What is a Submersible Water Pump and How Does it Work?

-

Why Choose an Electric Water Pump: Top Benefits and Considerations

-

Top 10 Motor Pump Brands You Should Consider for Efficiency and Reliability

COMPANY INFO

Copyright © 2025. Rotech Pumps & Systems Inc. All rights reserved.