Top Factors Influencing Water Pump Price You Need to Know

Understanding the factors that influence water pump price is essential for anyone looking to purchase or invest in this vital equipment. Water pumps play a crucial role in various applications, from agricultural irrigation to industrial processes and residential water supply. However, potential buyers often find themselves grappling with the seemingly unpredictable price tags associated with these devices. Several elements contribute to the fluctuation in water pump prices, making it imperative to have a comprehensive understanding of what drives these costs.

In this discussion, we will delve into the key factors that affect water pump price. From the type of pump and its intended application to material composition and technological advancements, each aspect can significantly impact overall expenses. Additionally, market dynamics, supply chain considerations, and regional pricing variations further complicate the landscape of water pump costs. By gaining insight into these critical determinants, buyers can make more informed decisions and potentially save money in their investment.

Factors Affecting the Cost of Water Pumps: An Overview

When considering the cost of water pumps, several key factors play a significant role in determining their final price. One primary influence is the pump type, which varies widely in design and capability. For instance, centrifugal pumps tend to be less expensive due to their simpler construction, while submersible pumps, designed for specific applications, can carry a higher price tag. According to a recent industry report by Grand View Research, the global water pump market was valued at approximately $40 billion in 2022 and is projected to witness a compound annual growth rate (CAGR) of 6.3% through 2030, reflecting the growing demand and technological advancements in the sector.

Material quality and durability also significantly impact the cost of water pumps. Pumps constructed from high-grade materials like stainless steel or bronze tend to be pricier yet provide better longevity and performance in challenging environments. Additionally, the pump's horsepower and capacity, tailored to handle specific flow rates and pressures, can escalate costs. As outlined by Research and Markets, investments in energy-efficient pumps are expected to rise, leading to increased initial costs but long-term savings on energy bills due to improved efficiency.

Tips: When shopping for water pumps, consider evaluating your specific needs to choose the most appropriate pump type, which can lead to substantial cost savings. It's also wise to invest in quality materials, as they may reduce maintenance costs over time. Lastly, always factor in energy efficiency ratings to optimize operating costs in the long run.

Top Factors Influencing Water Pump Price You Need to Know

| Factor | Description | Impact on Price |

|---|---|---|

| Type of Pump | Different types of pumps (submersible, centrifugal, etc.) have varying costs based on design and materials. | High |

| Material | Pumps made from stainless steel or bronze are generally more expensive than those made from plastic. | Medium to High |

| Power Source | Electric pumps usually cost more than manual pumps due to the added technology. | High |

| Flow Rate | Higher flow rates generally result in higher costs due to increased capacity requirements. | Medium to High |

| Brand Reputation | Established brands may charge a premium for reliability and service. | Medium |

| Warranty and Support | Pumps with longer warranties or better customer service typically have higher prices. | Medium |

| Installation Costs | The complexity of installation can add to overall costs, impacting the total investment. | Varies |

Market Demand and Its Impact on Water Pump Pricing

Market demand is a key driver of water pump pricing, significantly influencing how manufacturers and suppliers strategize their offerings. When demand for water pumps rises due to increased agricultural production, construction projects, or enhanced infrastructural development, prices tend to follow suit. This correlation is especially noticeable in regions experiencing rapid population growth or urbanization, where the necessity for efficient water management systems increases, pushing consumers to invest more in quality pumps.

Moreover, seasonal fluctuations can create varying demand patterns. For instance, during periods of drought, the need for irrigation solutions soars, leading to heightened competition among buyers for available products. Conversely, in times of economic downturn, demand may decrease as consumers prioritize essential expenditures over equipment upgrades or new installations. Consequently, water pump manufacturers adjust their pricing strategies to reflect these changing demand dynamics, making it imperative for buyers to stay informed about market trends to make timely purchasing decisions.

Types of Water Pumps and Their Price Variations

Water pumps come in a variety of types, each designed for specific applications, which contributes significantly to their price variations. Centrifugal pumps, for instance, are commonly used in industrial settings and agricultural applications, thanks to their efficiency in moving large volumes of water. The price range for centrifugal pumps can vary based on their size and capabilities, typically ranging from a few hundred to several thousand dollars. Their construction materials, such as stainless steel or plastic, also play a crucial role in determining cost.

Another prevalent type is submersible pumps, often employed in residential settings for groundwater extraction or in sump applications. These pumps are designed to operate while submerged in water, making their design and manufacturing process more complex. As a result, prices for submersible pumps can be higher than those for standard surface pumps, with costs starting at around one hundred dollars and escalating based on horsepower and depth of operation. Additionally, specialized pumps, such as diaphragm or water pressure booster pumps, tend to have unique pricing structures due to their specialized functionality and the engineering involved in their design.

Top Factors Influencing Water Pump Prices

This chart illustrates the average prices of various types of water pumps. The prices vary based on the type of pump and its application. Understanding these factors can help you make informed purchasing decisions.

Material and Manufacturing Costs in Water Pump Pricing

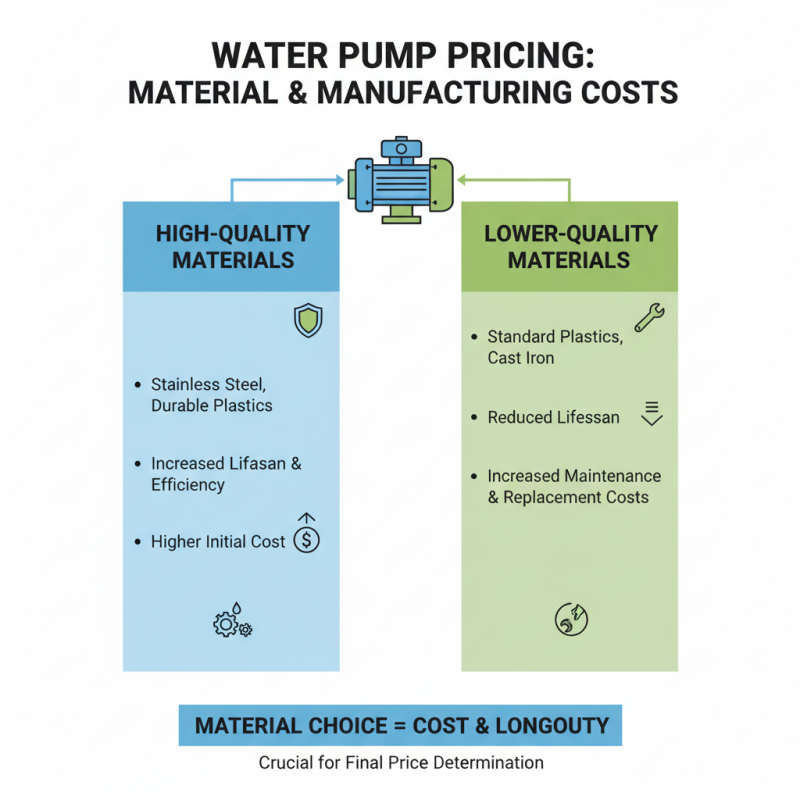

When it comes to the pricing of water pumps, material and manufacturing costs play a crucial role in determining the final price. The choice of materials used in the construction of water pumps significantly impacts production expenses. High-quality materials, such as stainless steel or durable plastics, can enhance the pump's lifespan and efficiency, but they typically come with a higher price tag. Conversely, opting for lower-quality materials might reduce initial costs, but could lead to increased maintenance and replacement expenses over time.

Manufacturing processes also contribute substantially to the overall cost structure of water pumps. Advanced techniques, such as precision machining and assembly, require skilled labor and sophisticated equipment, which can escalate production costs. Furthermore, the complexity of the pump design may require additional time and resources, further influencing the price. Companies must balance these factors to produce a cost-effective product that meets market demands while ensuring reliability and performance. Understanding these dynamics can help consumers make informed choices regarding their water pump purchases.

Brand Reputation and Its Influence on Water Pump Prices

When it comes to the pricing of water pumps, brand reputation plays a crucial role in shaping consumer perceptions and purchase decisions. According to a report from Research and Markets, nearly 70% of consumers consider the brand name as a key factor when selecting a water pump. Established brands often command higher prices due to their long-standing reputation for quality and reliability. This trust is built through years of rigorous testing, consistent performance, and a commitment to customer service, which can make consumers willing to pay a premium.

Furthermore, a survey conducted by The Freedonia Group highlights that brand reputation can significantly impact market dynamics, with branded pumps typically being 15-25% more expensive than unbranded alternatives. The loyalty to reputable brands often stems from their perceived value—customers believe that these products are more durable, efficient, and backed by better warranty offerings. As the water pump industry continues to evolve, brands that invest in reputation management and customer satisfaction can leverage these factors to not only maintain but also enhance their pricing strategies in a competitive marketplace.

Related Posts

-

Top Trends in Water Pumps: Harnessing Data-Driven Insights for Optimal Performance in 2023

-

Why You Should Choose a Self Priming Water Pump for Your Home and Garden Needs

-

Top Trash Pumps of 2025 for Efficient Water Removal and Waste Management

-

Why You Should Choose a Submersible Sump Pump for Your Home Drainage Needs

-

10 Essential Tips for Choosing the Right Goulds Water Pump for Your Needs

-

The Essential Guide to Self Priming Centrifugal Pumps: How They Work and Their Key Applications

COMPANY INFO

Copyright © 2025. Rotech Pumps & Systems Inc. All rights reserved.