Ultimate Guide to Using a Pump Catalog with Actionable Tips for Success

In the ever-evolving world of fluid management, the importance of utilizing a comprehensive pump catalog cannot be overstated. Industry expert John Smith, a leading consultant in pump solutions, emphasizes, "A well-organized pump catalog is not just a resource; it's a roadmap that guides engineers and operators toward optimal efficiency and reliability." With countless options available, understanding the nuances of different pump types, designs, and applications is critical for making informed decisions.

This ultimate guide delves into the effective use of a pump catalog, equipping professionals with actionable tips for success. Whether you’re selecting industrial pumps for large-scale operations or specialized pumps for niche applications, mastering the nuances of pump catalogs can significantly streamline the selection process. By leveraging the wealth of information available, users can ensure they are not only choosing the right equipment but also optimizing operational performance and enhancing safety standards.

Join us as we explore how to navigate the complexity of pump catalogs and harness their full potential, transforming the often daunting task of pump selection into a more efficient and informed process. Understanding the core elements of a pump catalog will empower you to make decisions that resonate throughout your organization, ultimately leading to greater productivity and sustainability.

Understanding the Basics of Pump Catalogs: What You Need to Know

When delving into the basics of pump catalogs, it’s essential to understand their structure and purpose. A pump catalog serves as a comprehensive guide that lists various types of pumps, their specifications, and intended applications. Familiarizing yourself with this essential tool allows for informed decision-making when selecting the right pump for a specific task. The catalog typically includes key information such as flow rates, pressures, materials, and operational environments, enabling users to assess compatibility with their project requirements effectively.

Additionally, knowing how to navigate a pump catalog can significantly enhance your selection process. Look for categorization, which may include centrifugal, positive displacement, and special-purpose pumps, each designed for distinct functions. Pay attention to the technical data provided alongside each product; this information is crucial for ensuring that the selected pump will meet the operational demands without performance issues. Furthermore, utilizing an organized approach to compare multiple options within the catalog can lead to better outcomes and more efficient procurement processes, ultimately supporting project success.

Key Components of a Pump Catalog: A Detailed Overview

When diving into the key components of a pump catalog, understanding the essential elements is crucial for making informed decisions. A comprehensive pump catalog not only showcases the products but also presents detailed specifications and performance metrics. According to industry reports, the global pump market is projected to reach $65 billion by 2026, highlighting the importance of precise data in selecting the right system. Key components typically include pump types, dimensions, materials, flow rates, and efficiency ratings, each playing a critical role in the selection process.

Equally important is the catalog’s layout, which should facilitate easy navigation. Users often seek data on operational costs, maintenance requirements, and ease of installation, all of which can influence the decision-making process. A study by the Hydraulic Institute revealed that nearly 40% of pump failures are linked to improper selection, often due to insufficient information. By providing clear and concise details, along with comparative analyses of different pump models, the catalog can significantly reduce the risk of costly errors, ensuring that users can confidently choose the most suitable pump for their applications.

Step-by-Step Guide to Navigating Your Pump Catalog Effectively

Navigating a pump catalog can feel overwhelming, especially with the vast array of options available. To effectively utilize your pump catalog, start by familiarizing yourself with the layout and organization of the content. Most catalogs are divided into sections based on pump types, applications, or specifications. This structured format allows you to quickly locate the specific type of pump you’re interested in, making the search process more efficient.

Tips: Before diving into the catalog, create a checklist of your requirements. Consider factors such as flow rate, capacity, and material compatibility. This will serve as a reference point, guiding you through the various options and helping you filter out unsuitable products. Additionally, don’t hesitate to consult catalog indices or charts that compare critical specifications at a glance.

Another essential step is to pay close attention to the labeling and descriptions within the catalog. Each pump will usually come with detailed technical data, including performance curves and installation instructions. Understanding this information will not only help you make informed decisions but also aid in troubleshooting should issues arise later.

Tips: Take notes as you browse, highlighting models that meet your criteria and any specific features or prices. This will create a personalized reference that you can refer back to when discussing options with colleagues or during the decision-making process.

Ultimate Guide to Using a Pump Catalog with Actionable Tips for Success

| Pump Type | Application | Flow Rate (GPM) | Head (Feet) | Efficiency (%) |

|---|---|---|---|---|

| Centrifugal Pump | Water Transfer | 100 | 45 | 85 |

| Submersible Pump | Sewage | 80 | 30 | 75 |

| Diaphragm Pump | Chemical Transfer | 60 | 50 | 80 |

| Gear Pump | Oil and Lubricants | 50 | 40 | 70 |

| Peristaltic Pump | Food Processing | 40 | 25 | 90 |

Using Pump Specifications for Optimal Selection and Performance

When selecting a pump for a specific application, understanding the pump specifications is vital for optimal performance. Key specifications such as flow rate, head pressure, and efficiency ratings can significantly influence the suitability of a pump for a given job. By carefully analyzing these parameters, users can match the pump's capabilities to their operational requirements. For instance, selecting a pump with a flow rate that aligns with the demand of the system ensures consistent performance while minimizing energy waste.

Additionally, considering the material compatibility and environmental conditions is essential for the longevity and efficiency of the pump. Different applications require pumps made from materials that resist corrosion, abrasion, or temperature changes. Knowing the fluid properties—such as viscosity, density, and chemical composition—can guide users in choosing a pump that not only meets performance expectations but also endures the specific operational environment. By leveraging detailed pump specifications, users can make informed decisions that lead to increased efficiency and reduced downtime.

Pump Specifications and Performance Analysis

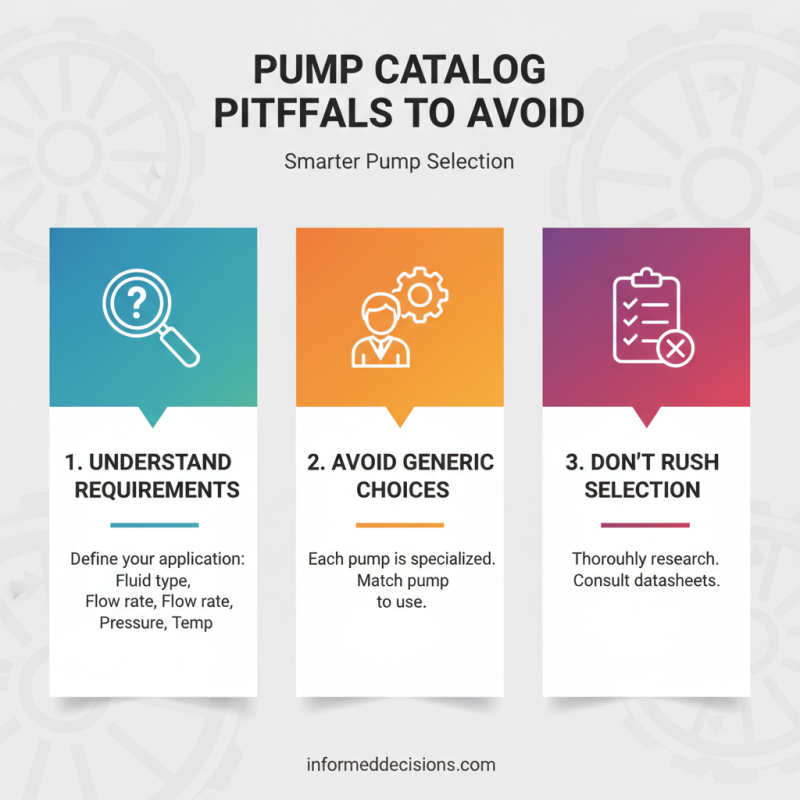

Common Mistakes to Avoid When Using a Pump Catalog for Decision Making

When utilizing a pump catalog for decision-making, it's crucial to avoid common pitfalls that can lead to misguided choices. One frequent mistake is not thoroughly understanding your specific application requirements before diving into the catalog. Each pump is designed for particular uses, and overlooking these specifics can result in selecting an inappropriate model.

Tips for success include taking time to clearly outline your operational needs, such as flow rate, pressure, and fluid type. By having this information ready, you can filter options in the catalog more efficiently. Additionally, it’s beneficial to consult with technical experts who can provide insights based on their experience, helping you avoid assumptions that may misguide your selection.

Another common error is failing to consider the pump’s lifecycle and maintenance needs. Many users focus solely on upfront costs, ignoring the long-term implications of performance and upkeep. To counter this, review the total cost of ownership estimates included in the catalog. Prioritizing durability and serviceability in your evaluation can lead to better investment choices and enhanced operational reliability.

Related Posts

-

Ultimate Pump Catalog Guide with Top 10 Pump Types to Maximize Efficiency

-

Unlocking the Power of Submersible Water Pumps: Your Guide to Efficient Water Management

-

Why Choosing a High Quality Centrifugal Pump Is Essential for Your Business

-

10 Essential Tips for Choosing the Right Goulds Water Pump for Your Needs

-

Top Benefits of Using Submersible Trash Pumps for Efficient Waste Removal

-

Why You Should Choose a Self Priming Water Pump for Your Home and Garden Needs

COMPANY INFO

Copyright © 2025. Rotech Pumps & Systems Inc. All rights reserved.