What is a Submersible Water Pump and How Does it Work?

When it comes to managing water efficiently, the submersible water pump stands out. These pumps are designed to operate underwater, making them ideal for various applications, from draining flooded basements to irrigation in agriculture. Tom Johnson, a renowned expert in fluid mechanics, once said, "Understanding the submersible water pump is key to optimizing water management systems."

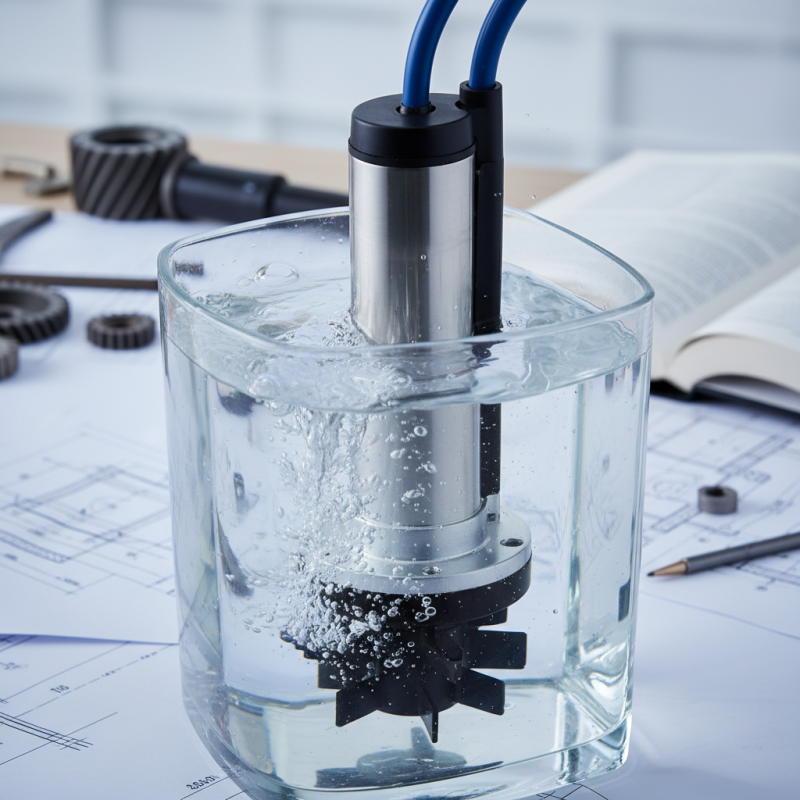

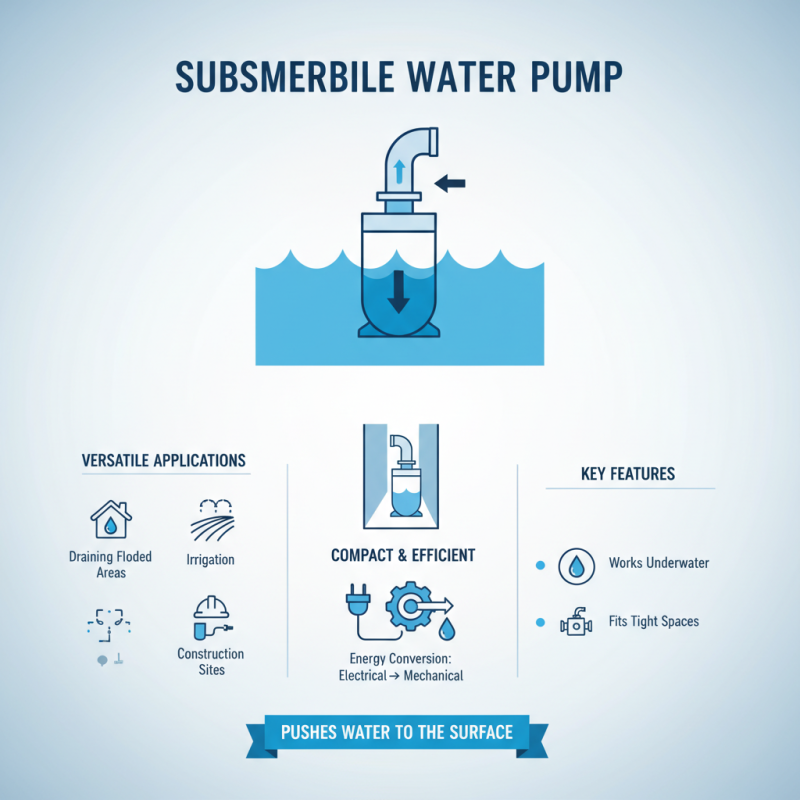

Submersible water pumps work by converting electrical energy into mechanical energy. This process allows them to move water effortlessly. They consist of a motor that drives an impeller, drawing water in and pushing it to the surface. The simplicity of their design is often overlooked, yet it directly affects their effectiveness. Some people find it challenging to maintain these pumps, leading to performance issues over time. Regular maintenance is essential.

While these pumps are powerful, they can be prone to wear and tear. Users sometimes neglect to check for signs of damage. This oversight can lead to costly repairs or replacements. Understanding how a submersible water pump functions can help prevent these problems and ensure longevity. It's a reminder that, even in technology, attention to detail makes a difference.

What Defines a Submersible Water Pump?

A submersible water pump is a device designed to function while submerged in fluid. It operates efficiently underwater, drawing water in and pushing it out through a discharge pipe. This pump is typically sealed in a protective casing to prevent electrical components from being exposed to water. The design allows the motor to operate in the fluid, which cools it and enhances its performance.

The defining feature of a submersible pump is its ability to submerge completely. Unlike regular pumps, these devices do not require priming, which simplifies their use. They are common in various settings, including wells, ponds, and flooded basements. Many submersible pumps are also energy-efficient, which can lead to lower operating costs over time. However, they can pose challenges in maintenance due to their working environment.

Understanding the mechanics of a submersible pump can reveal potential issues. Sometimes, they can become clogged with debris, leading to reduced efficiency. Regular inspection is crucial to ensure longevity. Users should also be aware of the risks of electrical failure. These devices require careful handling to avoid costly mishaps.

Submersible Water Pump Capacity Comparison

This bar chart shows the flow rate in gallons per hour (GPH) for various horsepower (HP) ratings of submersible water pumps. As the horsepower increases, the flow rate capability of the pumps also increases, making them suitable for different applications like residential, agricultural, and industrial use.

Key Components of a Submersible Water Pump

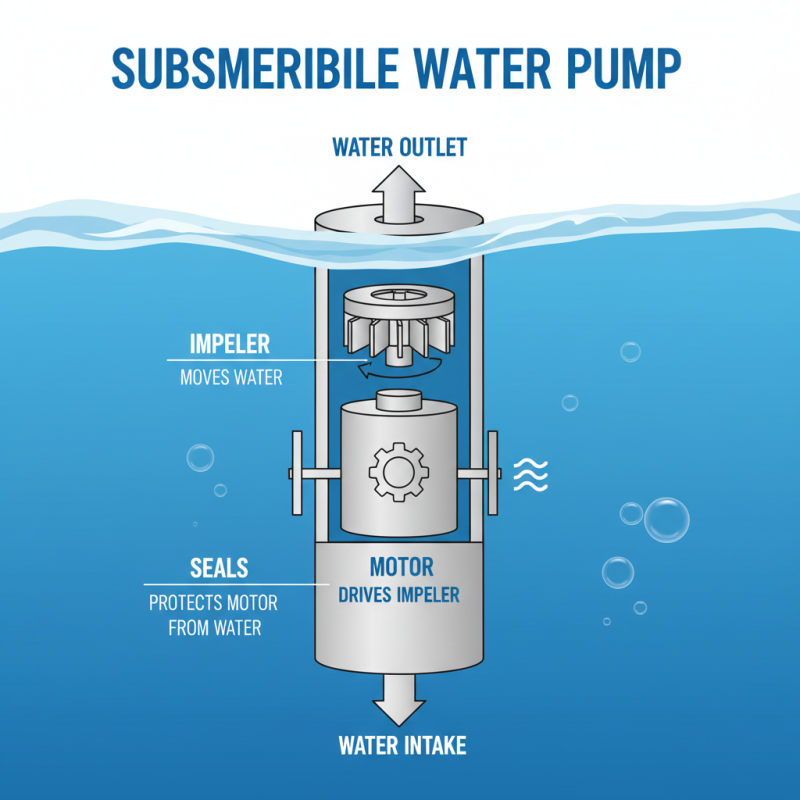

A submersible water pump is designed to function underwater. It features several key components that contribute to its operation. The main part is the motor, which drives the pump impeller. This impeller moves water, creating flow. Seals protect the motor from water, ensuring longevity.

Another essential component is the float switch. It detects water levels, automatically turning the pump on and off. This feature prevents overflow and dry running, safeguarding the motor. Additionally, the pump casing is vital as it houses these components and protects them during operation. Using robust materials like stainless steel can enhance durability.

Tips: Regular maintenance can enhance pump efficiency. Check the impeller for any blockages. Ensure the seals remain intact to avoid leaks. Consider installing a backup pump for emergencies. Remember, an ill-maintained pump may underperform or fail.

How Does a Submersible Water Pump Operate?

A submersible water pump is an effective tool for various applications. These pumps are designed to operate while fully submerged in water. They are often used for draining, irrigation, or even in aquariums. But how does a submersible water pump operate?

The motor of a submersible pump is sealed in a watertight casing. This design allows it to push water to the surface. With the aid of an impeller, water is drawn into the pump and then expelled. While this may sound simple, the mechanics behind it can be quite intricate. The pump must be properly placed and maintained. Neglecting these factors may lead to decreased efficiency or even failure.

Despite their robust design, submersible pumps can face challenges. For instance, debris in the water may clog the impeller. This can hamper performance. Regular checks and maintenance are crucial. Otherwise, you might find the pump isn’t working when you need it most. Understanding how these pumps work leads to better utilization and troubleshooting.

What is a Submersible Water Pump and How Does it Work?

| Feature | Description |

|---|---|

| Definition | A submersible water pump is a device used to pump water from deep underwater sources like wells, aquifers, or reservoirs. |

| Working Principle | These pumps are designed to be submerged in water and operate by converting rotational energy into hydraulic energy through a series of impellers. |

| Components | Key components include the motor, impeller, diffuser, mechanical seals, and a protection housing. |

| Advantages | High efficiency, ability to lift water from significant depths, and reduced risk of cavitation. |

| Applications | Used in agriculture, mining, municipal water supply, groundwater lowering, and emergency flood control. |

| Maintenance | Regular inspection of the motor and seals, along with cleaning of the intake screen to prevent clogging. |

Applications and Uses of Submersible Water Pumps

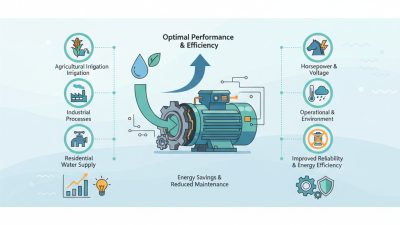

Submersible water pumps are versatile tools commonly used in various applications. They are designed to function underwater, making them ideal for draining water in flooded areas. Their compact size allows them to fit snugly in tight spaces. They work by converting electrical energy into mechanical energy, enabling them to push water to the surface efficiently.

In agriculture, submersible water pumps play a crucial role. They are used to irrigate crops by drawing water from wells or ponds. This ensures that plants receive a steady supply of water, particularly during dry spells. However, farmers must be cautious about the pump's capacity. An oversized pump can lead to resource wastage and imbalance in water supply.

In residential settings, these pumps are often used in basements or pools. Homeowners rely on them to remove excess water and prevent damage. Yet, it's important to periodically check the pumps for wear and tear. Neglecting maintenance can lead to bigger issues down the line. While submersible pumps are efficient, understanding their limitations is vital for optimal performance.

Maintenance Tips for Submersible Water Pumps

Submersible water pumps are essential for draining water from basements or removing excess water from gardens. Regular maintenance is crucial for optimal performance. Neglecting care can lead to failures or reduced efficiency.

One of the simplest tips is to check the pump for debris. Inspect the intake screen monthly. Remove clogs that can hinder performance. Clean it gently to avoid damage. Regular checks can prevent issues during heavy rains.

Another key aspect is to ensure proper lubrication. Some models require periodic oil changes. Refer to the manufacturer’s guidelines if available. Ignoring this can shorten the pump's lifespan.

Before winter, it's wise to inspect seals and connections. Frozen water can cause serious damage. If unsure, consider using a moisture meter to detect potential issues. Remember that small problems can escalate if not addressed. Regular attention to these details can save money and headaches later.

Related Posts

-

Unlocking the Power of Submersible Water Pumps: Your Guide to Efficient Water Management

-

Top Submersible Water Pump Options for Your Needs?

-

2025's Top 10 Submersible Pumps to Enhance Your Water Management Solutions

-

2026 Best Centrifugal Pump Options for Your Needs?

-

Top 10 Tips for Choosing the Best Water Pump for Your Home

-

Why You Should Choose the Right Water Pump Motor for Your Needs

COMPANY INFO

Copyright © 2025. Rotech Pumps & Systems Inc. All rights reserved.