Top Trash Pumps of 2025 for Efficient Water Removal and Waste Management

In the dynamic realm of water removal and waste management, the importance of choosing the right equipment cannot be overstated, particularly when it comes to trash pumps. As we delve into the top trash pumps of 2025, industry experts emphasize the critical role these machines play in efficient operation. John H. Smith, a well-respected engineer with over two decades of experience in fluid management, states, "The right trash pump can make all the difference when it comes to handling debris-laden water, ensuring that the process remains smooth and effective."

As water management becomes increasingly vital in various sectors, from construction sites to agricultural applications, the demand for powerful and reliable trash pumps is soaring. These pumps are designed not only to manage water effectively but also to handle solids and debris, which can complicate traditional pumping systems. Therefore, selecting a top-rated trash pump can significantly enhance operational efficiency and reduce downtime.

Looking ahead to 2025, advancements in technology promise to revolutionize the trash pump industry. Features such as improved energy efficiency, enhanced durability, and advanced automation will change the game for users who rely on these essential machines. By staying informed on the latest trends and innovations, businesses can ensure they are equipped with the best solutions for their water removal and waste management needs.

Overview of Trash Pumps and Their Importance in Waste Management

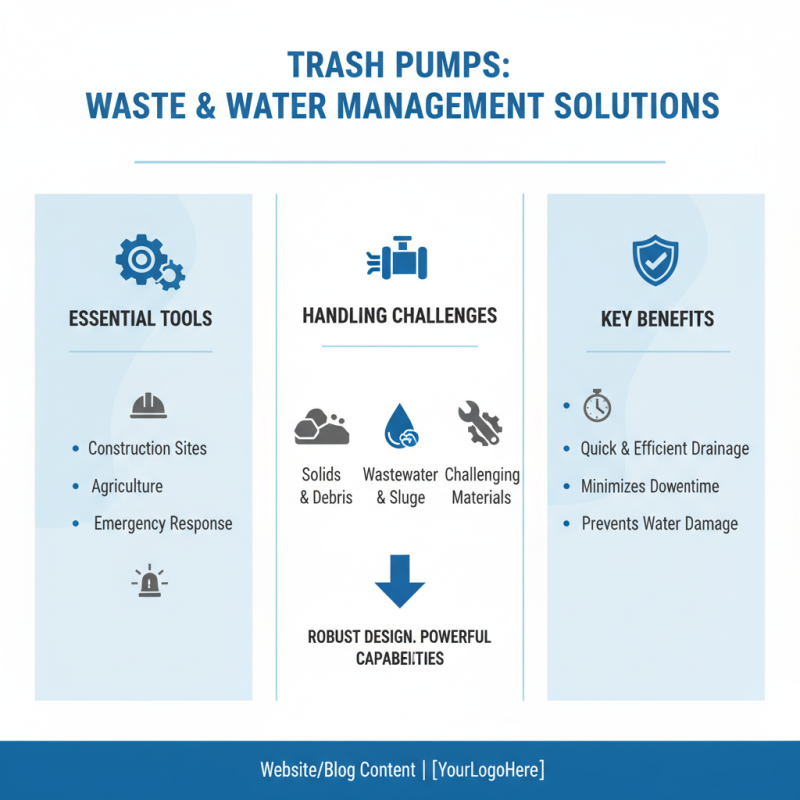

Trash pumps are essential tools in waste management and water removal, particularly in construction sites, agriculture, and emergency response situations. These pumps are designed to handle solids and debris, making them effective for pumping wastewater, sludge, and other challenging materials. Their robust design and powerful capabilities allow for quick and efficient drainage, minimizing downtime and preventing damage from standing water.

When choosing a trash pump, consider the pump's capacity, head height, and the type of solids it can handle. It is crucial to select a pump that meets the specific demands of your project to ensure optimal performance. Additionally, maintaining your trash pump by regularly checking for wear and tear can prolong its lifespan and efficiency.

Tips for using trash pumps include ensuring proper setup to prevent airlock issues and always following the manufacturer’s guidelines for operation. Moreover, wearing protective gear when handling waste materials can safeguard against potential hazards. Regularly cleaning the pump after use will also help maintain its performance and readiness for future tasks.

Key Features to Look for in Top Trash Pumps for 2025

When selecting a trash pump for efficient water removal and waste management in 2025, there are several key features to consider. First and foremost, the pump's capacity is crucial; a high flow rate allows for quicker removal of water and debris, making it ideal for large-scale projects and emergency situations. Look for pumps with a minimum flow rate of 2000 gallons per hour to ensure effective operation. Additionally, both the size of the pump impeller and the maximum solid handling size are important factors, as they determine the types of materials the pump can handle without clogging.

Another essential feature is the material construction of the pump. In 2025, durable, corrosion-resistant materials are increasingly preferred, as they extend the pump's lifespan and enhance its reliability in challenging environments. Stainless steel and high-quality plastics provide excellent durability. Furthermore, consider the pump's portability and ease of use; features such as lightweight designs, comfortable handles, and built-in float switches improve user experience. Advanced designs may also incorporate automatic shut-off mechanisms to prevent dry running, ensuring safety and efficiency during operation.

Comparison of Leading Trash Pump Brands and Models for Efficient Use

When it comes to efficient water removal and waste management, choosing the right trash pump is crucial. Several brands have established themselves as leaders in the market, each offering unique features tailored to different needs. For instance, Honda's trash pumps are renowned for their fuel efficiency and durable construction, making them an excellent choice for heavy-duty tasks. Their models often come equipped with powerful engines and advanced clog-resistant impellers, which enhance performance in debris-laden water.

In contrast, the Goulds brand stands out with its innovative designs that prioritize portability and ease of use. Their submersible trash pumps are lightweight yet powerful, allowing for quick deployment in various environments. Users often highlight the ease of maintenance and reliability that come with Goulds pumps. Additionally, brands like Tsurumi and Wayne offer specialized models aimed at specific applications, such as construction sites or residential flooding. By understanding the strengths of each brand, users can select a pump that not only meets their immediate needs but also provides long-term efficiency and reliability in waste management.

Maintenance Tips for Prolonging the Life of Your Trash Pump

Proper maintenance is essential for maximizing the lifespan and efficiency of your trash pump. Regularly inspecting your pump for wear and tear is a crucial first step. Look for signs of corrosion, cracks, or loose fittings, and address any issues immediately. It's also important to keep debris out of the pump, as clogging can lead to overheating and eventual failure. Consider using a strainer or filter to help keep unwanted materials from entering the pump system.

Additionally, routine cleaning and lubrication are vital for maintaining optimal performance. After each use, make sure to clear any accumulated sediment or sludge that might hinder the pump’s function. Lubricating the moving parts will ensure smooth operation and reduce the risk of mechanical failure. Always refer to your manufacturer's guidelines for the recommended cleaning and lubrication schedule. By adhering to these maintenance practices, you can extend the life of your trash pump and ensure it performs effectively whenever you need it.

Innovations in Trash Pump Technology for Enhanced Performance

The advancements in trash pump technology are paving the way for more efficient water removal and waste management solutions in 2025. With the global construction and wastewater management markets expected to grow at a CAGR of 5.5% through 2027, the demand for innovative trash pumps is on the rise. Recent reports highlight how manufacturers are incorporating smart sensors and IoT connectivity, allowing for real-time monitoring and enhanced efficiency. This shift not only improves performance but also minimizes operational costs by ensuring these pumps operate only when needed.

When selecting a trash pump, consider the importance of horsepower and impeller design. Pumps with multi-channel impellers can handle larger debris and provide a significant reduction in clogging incidents. Additionally, look for models with energy-efficient motors; data from the U.S. Department of Energy indicates that energy-efficient pumps can save up to 30% in energy costs compared to standard models.

**Tips:** Always assess the specific requirements of your project, including the type of waste and water conditions, before purchasing a pump. Regular maintenance is also key to longevity; ensure that you check filters and impellers frequently to keep your trash pump operating at peak performance. Lastly, consult with professionals for the best recommendations tailored to your needs, as this can lead to substantial savings and improved efficiency in waste management.

Top Trash Pumps of 2025 for Efficient Water Removal and Waste Management

| Model | Max Flow Rate (GPM) | Max Head (Feet) | Pump Material | Weight (lbs) | Fuel Type |

|---|---|---|---|---|---|

| TP-2025A | 200 | 25 | Aluminum | 45 | Gasoline |

| TP-2025B | 180 | 30 | Cast Iron | 60 | Electric |

| TP-2025C | 220 | 35 | Stainless Steel | 50 | Diesel |

| TP-2025D | 150 | 20 | Polypropylene | 40 | Gasoline |

Related Posts

-

Why You Should Choose a Submersible Sump Pump for Your Home Drainage Needs

-

Top Trends in Water Pumps: Harnessing Data-Driven Insights for Optimal Performance in 2023

-

10 Essential Tips for Choosing the Right Goulds Water Pump for Your Needs

-

Why You Should Choose a Self Priming Water Pump for Your Home and Garden Needs

-

Understanding Goulds Water Pumps Efficiency and Longevity in Modern Applications

-

10 Essential Tips for Choosing the Best Self Priming Pump for Your Needs

COMPANY INFO

Copyright © 2025. Rotech Pumps & Systems Inc. All rights reserved.